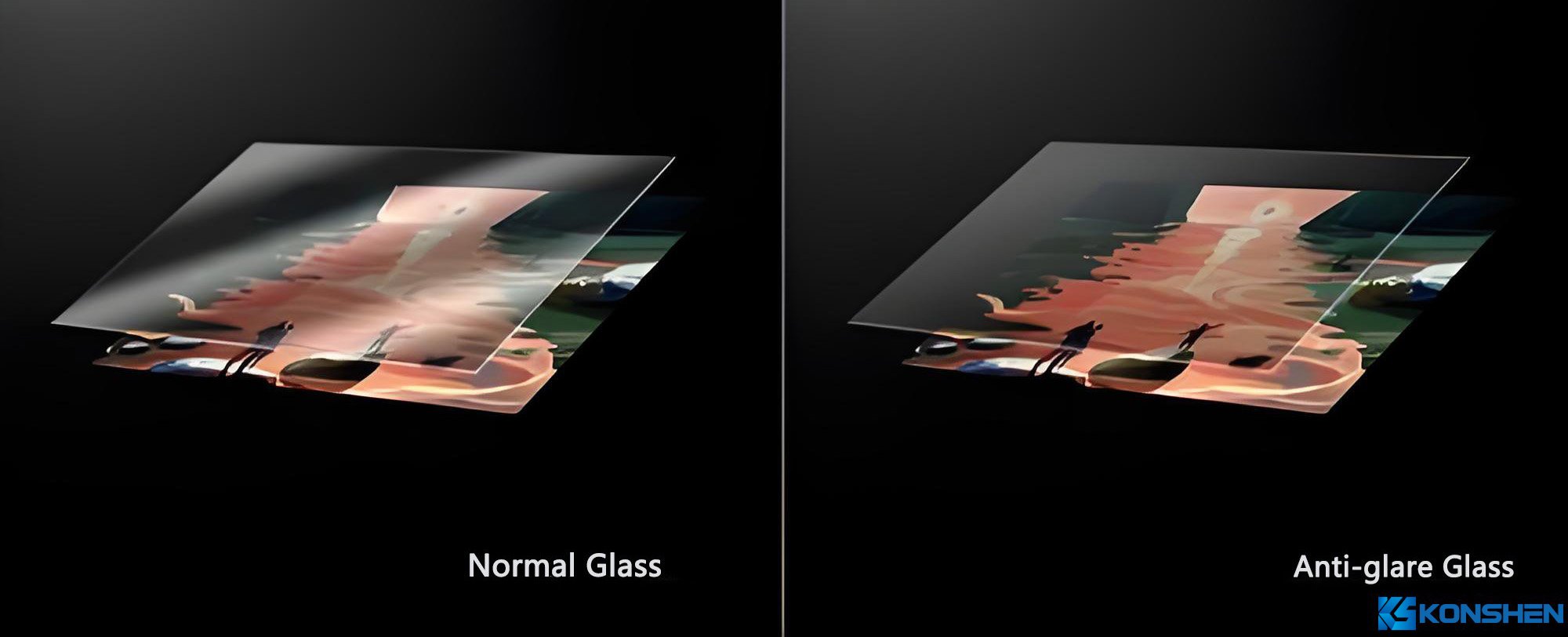

Anti-glare glass, often used to reduce visual discomfort from reflections, offers numerous applications in various industries. Understanding its key properties helps users select the right material for their specific needs. This news explores the 6 essential characteristics of anti-glare glass: Gloss, Transmittance, Haze, Roughness, Distinctness of Image and Thickness.

|

1.1 GlossGloss refers to the smoothness and reflectivity of a glass surface. The greater the gloss, the more reflective the glass surface becomes, enhancing the clarity of the glass. Generally, the glossiness of anti-glare glass is between 10 and 110 GU (gloss unit). The primary goal of AG coated glass is to scatter light, reducing reflections. Gloss is directly tied to clarity and inversely related to haze and roughness.Gloss≈110: Used in automotive applications where high clarity is essential. AR, AF Coating are also often used in combination. Gloss≈90: Common used in medical devices or cash registers, where clarity is prioritized. 60<Gloss<90: Suitable for outdoor displays or machinery exposed to bright sunlight, where glare reduction is critical. 30<Gloss<60: Preferred for environments with intense sunlight, such as billboards or platform displays. Gloss<30: Ideal for mousepad, touch-sensitive devices, as it enhances the tactile experience and minimizes fingerprint marks. |

|

1.2.Light TransmittanceFor anti-glare glass, transmittance is influenced by the level of gloss. The higher the gloss, the more light passes through, though it generally doesn't exceed 92%. Usually, the transmittance should reach more than 88%. High transmittance can ensure that the glass allows light to pass through fully while reducing reflection, making the displayed content clear and bright. |

|

1.3.RoughnessSurface roughness describes the small peaks and valleys on a material's surface, which are typically a result of its manufacturing process. A rougher surface contributes to greater anti-glare properties but can also affect clarity. Thus, the balance between roughness and gloss is key to achieving the desired visual effect. |

|

1.4.HazeHaze refers to the amount of scattered light passing through the glass, causing a cloudy or diffused appearance. A high haze value correlates with lower clarity and affects image quality. Essentially, the greater the haze, the less clear the glass is, impacting visual clarity and transparency. |

1.5.Distinctness of Image (DOI)Distinctness of Image is a key indicator of image quality, influenced by the size of surface particles. Smaller particles result in higher pixel density, leading to clearer images. In anti-glare glass, finer particles enhance the clarity and visual performance, ensuring a sharper and more distinct display. |

|

|

1.6.ThicknessThe thickness of AG glass varies according to different application requirements. Common thicknesses are 0.55mm, 0.7mm, 1.1mm, 2.0mm, 3.0mm, etc. For example, AG glass used in mobile phone screens is usually thinner, while that used in household electronic devices is relatively thicker to meet the requirements of strength and safety. |

2.Benefits of the AG Glass

Through the etching or spraying coating technology, the surface hardness is enhanced, and the ability to resist scratches and wear during daily use is improved. For example, after the chemical etching AG glass is strengthened, the scratch resistance of its surface is comparable to that of ordinary glass.

The special surface structure and treatment endow it with a considerable degree of fingerprint resistance. It is not easy to adsorb impurities such as dust and oil stains, making cleaning and maintenance easier.

Chemical etching AG glass has the best durability. The surface is essentially still glass, and its product lifespan is comparable to that of tempered glass. The AG layer will not peel off due to environmental and usage factors.

Chemical etching AG glass can undergo cold processing such as grinding, cutting, and tempering, and the AG effect will not change after processing.

It can be applied not only to medium and large-sized products but also to small and miniature products, giving full play to its advantages. Moreover, it can maintain good performance consistency across products of different sizes.

3.1 Display FieldSmartphones, laptops, and tablet computers: It can effectively reduce screen reflection, help improve the viewing angle and display quality of the screen, reduce visual fatigue caused by light reflection, and is suitable for long-term use. |

|

3.2 Automotive FieldAutomotive central control screens: Enable drivers to clearly read the information on the central control screen under various lighting conditions, reduce the interference of reflection on the driving line of sight, and improve driving safety. |

|

3.3 Optical Instrument FieldTelescopes: Reduce the reflection on the surface of the lens, improve the light transmittance, making the observed images clearer and brighter, and at the same time avoid the irritation of glare to the eyes. |

|

3.4 Construction FieldBuilding curtain walls: Can not only ensure the lighting effect of the building but also effectively reduce the reflectivity of the glass surface, reduce light pollution, and provide a comfortable visual environment indoors. |

|

3.5 Medical FieldSuch as medical monitors, surgical lights, etc., it can provide clear image display and good lighting effects, reducing the interference of glare on the operation of medical staff. |

|

3.6 Other FieldsTouch screens: Widely used in various touch screen devices, such as self-service inquiry machines, cash registers, etc., to improve the visibility of the screen and the convenience of operation. |

|

Selecting suitable anti-glare glass involves understanding how each of these properties affects the material’s performance. Whether for a high-clarity display or a glare-reducing screen, considering these factors ensures the best choice for your specific application. KS Glass offer a large range of AG coated glass solutions tailored to meet your specific needs, combining performance and functionality seamlessly. Learn more about our AG glass solutions here.

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us